Properties and characteristics of both constructions

To go back to “Steps”, click here

Next Step: Laying the rope, click here

Samples and comparison

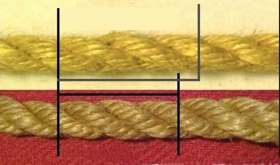

While they may have similar characteristics, not all ropes made in Japan or “Japanese” style are the same. As you can see from the samples on the left, even though they are constructed in the same way, the lay length may vary, just as “western” ropes also come in different types of lay.

[N.B. The yarn size will of course also play a part in the final result.]

Home-made jute rope, each strand twisted around a rayon core yarn, Japanese-style.

Comparison between a Japanese jute rope and a jute rope bought in Switzerland. Notice the difference in the length of lay, due to the different strand constructions.

Japanese sample

Swiss sample

Osada Steve

Naka-San

Esinem’s “Osaka”

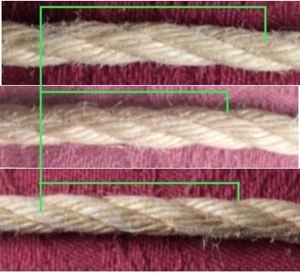

When a small number of yarns are twisted around a core yarn, they form a tube-like layer around that core, and all the yarns follow an identical helical path, as shown here.

The photos below clearly show the “tube”, created by the yarns laying parallel to one another, like a ribbon, around the 2 core yarns.

When there is no central core, each yarn potentially has a different helical path within the strand, as shown here. This “bunched strand” construction allows to a tighter twisting of the strands during fabrication.

It is my understanding that because of this, Japanese ropes appear to be looser-laid to the untrained eye.

However, if you try to make a “western-style” rope matching the length of lay of the Japanese model, you’ll end up with, at best, a lifeless rope, and at the worst an unusable rope, as it won’t have enough twist in the strands.

Cores made of natural fibres do not make a rope stronger: they mainly provide a material axis around which the outer yarns - or the strands, in the case of 4-stranded ropes - can arrange themselves in a stable way.

When under meaningful load, as the core is shorter than the other yarns, it will break (particularly with 4-stranded ropes), it will be the first yarn to break.

From my experimentations, using a stronger synthetic core yarn with some elasticity may reduce this phenomenon. However, to make my ropes stronger, i prefer to make bunched strands, allowing the added reinforcing yarn to share the same load as the natural fibre yarns.